Key Benefits of Using a Membrane Switch in Industrial Applications

Key Benefits of Using a Membrane Switch in Industrial Applications

Blog Article

Comprehending the Functionality of Membrane Switches Over for Interface Tools

The performance of membrane switches over represents a considerable development in interface layout, incorporating efficiency with aesthetic adaptability. These switches run with a multi-layered structure that converts individual interactions right into electric signals, enabling both compact designs and durability against ecological elements. As sectors progressively prioritize individual experience, recognizing the nuances of membrane layer switch modern technology ends up being essential. What ramifications do these improvements hold for future applications, and how might they redefine individual interactions across different devices?

What Are Membrane Layer Switches?

Membrane layer buttons are cutting-edge user interface gadgets that facilitate user communication with digital equipment. These versatile components are composed of several layers, including a graphic overlay, spacer, and a printed circuit layer. The layout enables a seamless combination right into different digital gadgets, boosting both the visual and useful facets of user interfaces.

Membrane switches are generally used in a variety of applications, from family home appliances to industrial machinery and clinical devices. Their building normally includes a thin profile, making them a perfect option for compact layouts. The responsive feedback provided by these buttons can be crafted to satisfy particular user preferences, ensuring effective communication between the user and the gadget.

Sturdiness is one more significant benefit of membrane buttons, as they are immune to dust, dampness, and chemicals, which improves their life expectancy popular environments. Additionally, these buttons can be tailored in regards to form, size, and graphic layout, permitting branding and user-specific features. Overall, membrane layer switches over represent a practical remedy for improving individual experience in electronic tools, integrating functionality with visual appeal in a reliable way.

How Membrane Layer Switches Job

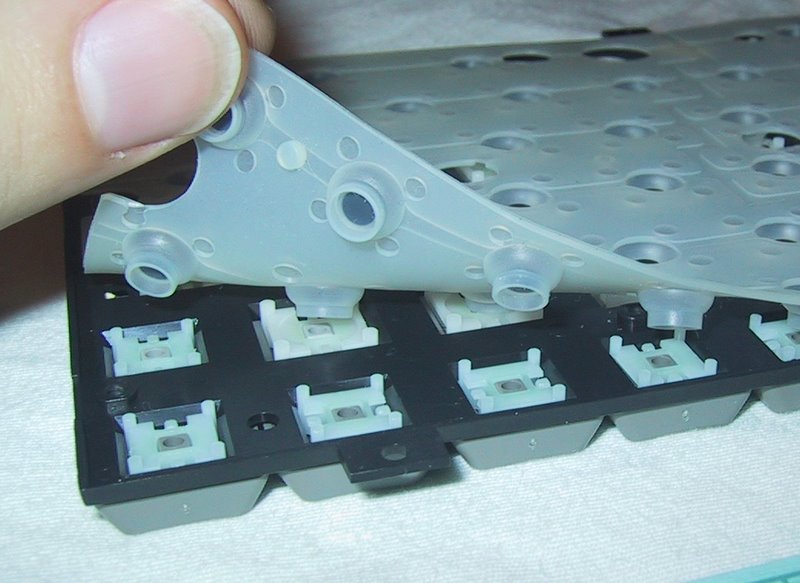

Operating on a simple principle, membrane changes utilize a split building to register individual input effectively. Each button consists of multiple layers, including a published circuit layer, a spacer layer, and a top graphic layer, which are made to interact effortlessly. When a customer presses the top layer, it compresses the spacer layer, bringing the conductive aspects of the circuit layer into contact with each various other.

This contact produces a closed circuit, signaling the gadget to perform a particular feature. The layout permits different arrangements, including responsive feedback, which can improve the customer experience by providing a physical feeling upon activation. The products made use of in membrane switches frequently include versatile substratums, such as polyester or polycarbonate, which make certain sturdiness and strength against deterioration.

Trick Benefits of Membrane Layer Switches

Another significant benefit is their compactness. Membrane buttons are thin like this and lightweight, which enables suppliers to conserve space in their tools without compromising functionality. This attribute is especially advantageous in applications where weight and quantity are critical considerations.

In addition, membrane buttons are immune to dust, wetness, and chemicals, boosting their toughness. This resilience expands their life-span and minimizes the need for constant replacements, resulting in cost financial savings in time.

Moreover, the responsive feedback provided by membrane buttons can be maximized to boost customer communication. They can consist of functions such as elevated buttons or distinct clicks, improving functionality and individual experience.

Applications Across Industries

Interface devices using membrane switches are widespread in a wide range of markets, showcasing their flexibility and capability. Membrane Switch. In the medical market, membrane layer buttons are essential to tools such as diagnostic devices and person monitoring systems, where their durability and simplicity of cleansing are essential for preserving hygiene criteria. In the vehicle industry, these switches are employed in dashboard controls and infotainment systems, giving a smooth and contemporary user interface for customers.

Moreover, the consumer electronic devices sector benefits from membrane layer switches in appliances and handheld gadgets, where portable layout and easy to use interfaces enhance individual experience. Industrial applications likewise take advantage of membrane layer switches for control panels in machinery and automation systems, emphasizing their robustness and resistance to severe settings.

In the aerospace and protection industries, membrane switches are made use of in cabin controls and devices, where dependability and performance under extreme problems are extremely important. In addition, the video gaming sector increasingly incorporates membrane layer buttons in controllers and gallery visit makers, adding to an appealing user experience. Overall, the flexibility of membrane layer changes enables their prevalent usage click for source across countless markets, highlighting their significance in contemporary individual interface layout.

Future Fads in Membrane Switch Over Innovation

Additionally, using innovative products, such as polycarbonate and polyester films, is expected to climb, providing improved resilience and resistance to ecological stressors. These materials add to the total longevity of membrane switches, making them ideal for harsher commercial applications.

Furthermore, the unification of smart technology, including IoT connectivity, will certainly make it possible for membrane switches to communicate with various other gadgets and systems, facilitating a more interactive individual experience. This pattern lines up with the expanding demand for smart gadgets across numerous fields, from medical care to consumer electronics.

Finally, personalization choices are prepared for to increase, permitting manufacturers to create bespoke solutions customized to specific user needs and preferences. These advancements will position membrane buttons as crucial components in the evolution of interface technology.

Final Thought

Finally, membrane layer switches over stand for a pivotal advancement in interface innovation, using a trusted and functional remedy for varied electronic applications. Their layered building helps with small style, while functions such as responsive comments enhance customer communication. The sturdiness against ecological elements further strengthens their utility throughout multiple sectors. As improvements in material science and touch picking up innovations continue, the capability and applicability of membrane layer buttons are anticipated to expand, enhancing their importance in modern-day electronic tools.

Report this page